The Center for Disease Control and Prevention came to Sioux Falls last week and toured the shuttered Smithfield Foods slaughterhouse, now the third-worst coronavirus hotspot in the nation. Yesterday, the state posted the CDC’s report on the meat company’s failed efforts to protect its workers from covid-19 and the CDC’s “discretionary and not required or mandated” recommendations on additional health safeguards the Chinese corporation can take when it starts making sausage again.

Smithfield told CDC that it set up two screening tents on opposite sides of the plant where a “contracted health care professional” took entering employees’ temperatures by thermal imaging and asked them if they had a cough or shortness of breath. Any employee showing 99.8°F or reporting symptoms went to see a nurse who took temperatures with an infrared thermometer and checked for symptoms. If that nurse found signs of covid-19, the employee was handed an English-language packet (40 languages are spoken among the workers), told to go home, and given two weeks (80 hours) paid sick leave. Prior to its full closure, Smithfield noticed a high concentration of coronavirus cases in the pork conversion department and gave everyone on that crew two weeks paid sick leave.

The CDC says Smithfield took several steps to separate employees: dividers at lunchroom tables, taped-off tables and extra tables in the hall and outside to spread out the lunch break crowd, reduced line speed in the ground seasoned pork department, and 800 plexiglass barriers. Nonetheless, CDC noticed that the maintenance and distribution workers still at the plant during the tour “were congregating less than 6 feet apart when away from their workstations.” CDC also saw employees wearing facemasks incorrectly.

The CDC found mostly manually operated hand sanitizer stations “in limited locations throughout the plant, notably at the entrances to the building and within cafeterias and break rooms.” Smithfield promised the CDC they’ll install more, up to 3,500, nearly one per employee.

Smithfield also said it is working on the following improvements:

- Install more than 100 new time clocks to prevent crowds during shift changes.

- Provide facemasks with moldable nosepieces to every employee and require their use.

- Attach face shields to hard hats for all non-administrative employees.

- Increase use of the Beekeeper app to receive mass messages from management (currently 1,400 of 3,700 employees have signed up to use it on their phones).

- Install more plexiglass barriers.

- Distribute hand sanitizer to line workers every half hour.

- Relax sick leave policies and eliminate premiums, copays, and waiting periods for coronavirus testing.

The CDC recommends additional anti-pandemic interventions:

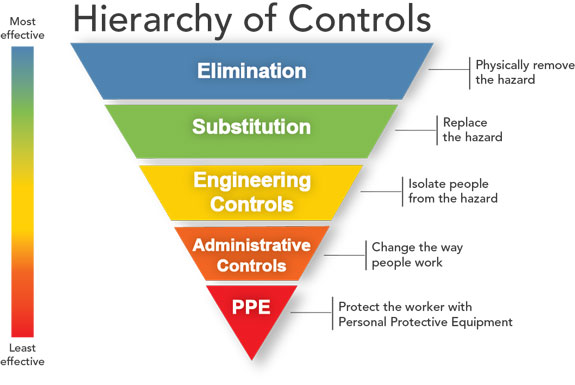

- Adopt the “hierarchy of controls,” a framework that prioritizes removing and replacing hazards, isolating workers from hazards, and changing the way people work over handing out personal protective equipment.

Hierarchy of Controls, CDC-National Institute for Occupational Safety and Health - To separate employees:

- Add more tape, floor markings, and other visual cues to urge employees to stay at least six feet apart at gear chekout, pig tattoo stations, sinks, time clocks, ride pickup area, cafeterias, break rooms, the employee bridge and main staircase, and the outdoor common area.

- Reduce and spread out lunch tables.

- Spread out lunchbox storage shelves.

- Set up outdoor break areas with heated tents (think beyond summer) and porta-potties.

- Spread locker rooms out into unused spaces.

- Make shift start and break times more flexible.

- Add more bathrooms and handwashing facilities.

- Spread out employees and slow the production lines.

- Separate more workstations with physical barriers.

- Add touchless time clocks.

- Reduce the size of training groups and move training online.

- Make one-way paths through the plant.

- Assign staff to monitor social distancing (and, we assume, to tell workers who aren’t following guidelines to get the heck away from each other, a thankless but necessary job).

- To control contagion:

- Urge everyone to cover their faces properly (nose and mouth!).

- Distribute face masks with minimal touching (i.e., don’t give Abdulahi a box of masks and tell him to walk down the production line handing them out to all of his colleagues; set them out on a table and have workers step forward one at a time, not in a crowd).

- Send sick employees home immediately.

- Scrub the crap out of sick employees’ work spaces.

- Make truck drivers and contractors wear masks on site.

- To improve screening:

- Screen everyone who enters the plant.

- Separate the flow of workers coming in from workers coming out.

- Help employees who test positive for coronavirus to find offsite housing separate from their families.

- Get better thermometers, and if you have to keep using thermal imaging, make sure you adjust it to entering employees’ height.

- Tell employees to report to supervisors if they get sick during work.

- Hand employees the CDC guidance on “What to Do If You Are Sick” on their way out the door (CDC has already done the translations!).

- Translate those screening packets into employees’ languages.

- Add large pictograms to all of the information posters and to the screeners’ stations to convey their questions about symptoms.

- To improve sick leave policies and practices:

- Be flexible.

- Make sure employees understand the benefits available.

- Don’t penalize employees who take sick leave due to coronavirus.

- Let employees stay home to take care of sick family members or of kids home from closed schools and daycares.

- Allow employees to donate sick leave and take advances on future sick leave.

- Stop requiring employees to provide a doctor’s note to validate sick leave.

- Make sure everyone follows the rules and is healthy before returning to work after a positive covid-19 test.

- To improve hygiene and sanitation:

- Encourage more handwashing, especially when moving from one task/place to another.

- Focus on adding handwashing stations around high-touch areas (including stairwells, breakroom entries and exits, and—word of the day!—doffing stations).

- Install no-touch sinks, soap and sanitizer dispensers, and paper towel dispensers (which CDC says are better than blow dryers!)

- Include hygiene stations in any temporary locker rooms and break areas.

- Scrub high-touch areas more often.

- Replace damaged plexiglass barriers

- Develop a protocol for sanitizing hard hats and face shields after every shift.

- Develop a protocol for storing hard hats instead of bringing them along into shared break areas.

- To improve training and communication:

- Enlarge and simplify signage (big blocks of text don’t work).

- Use more pictures/pictograms.

- Add more signs relevant to the immediate public health crisis and remove old signs.

- Put signs at eye level where workers can see them.

- Add video screens to give health messages.

- Play videos constantly in the cafeteria showing proper use of face coverings, handwashing, and social distancing.

- Broadcast guidance on handwashing and social distancing over the speakers during breaks and lunch.

- Provide health training in multiple languages.

- Use alternatives to in-person training: video, online, phone messages….

- Train everyone on new health policies and practices.

- Simplify the messaging.

- Make clear to employees that they can tell coworkers to put their masks on right and correct other errors in anti-coronavirus safeguards.

- Incentivize employee use of Beekeeper and other training channels.

- Provide more education to employees on health practices outside of work.

- To make better use of PPE:

- Demonstrate proper donning, use, and doffing of PPE.

- Train employees to stow PPE at work and not take it home.

- Train employees to wash their hands before and after handling PPE.

Yes, that’s a long list of actions. But those are the actions that any meatpacking plant—and, arguably, any business concentrating hundreds or thousands of people into one facility—needs to take to do business amidst the pandemic.

Smithfield says it “will thoroughly and carefully examine the report point by point and respond in full once our assessment is complete.” Governor Kristi Noem says she and the Department of Health “will continue to work with Smithfield and offer any assistance we can to help them implement these CDC recommendations so they can safely reopen this plant as soon as possible.”

https://thehill.com/homenews/494529-smithfield-foods-sued-over-missouri-plant-conditions

Being sued in Missouri federal court for not protecting workers enough.

Here’s a *brilliant* idea! 🙄🙄🙄

A member of Donald Trump’s task force to reopen the American economy suggested putting every American in a “space outfit” to safely get back to work.

“I was thinking this morning, and this is just kind of a thought experiment because I was thinking about this — why don’t we just put everybody in a space outfit or something like that? No. Seriously,” conservative economist Stephen Moore said in an interview with the New York Times.

is.gd/RS7wSz

Well, PPE for everyone is a key part of CDC’s recommendations for Smithfield.

Put a hanky, like the cowboys do, over your maw and then ride forth.

That is a great list. Smithfield better get busy installing ASAP.