In a Corrective Action Order issued April 9, the Pipeline and Hazardous Materials Safety Administration reports that TransCanada’s Keystone pipeline leaked about 400 barrels of tar sands oil south of Freeman due to a “girth weld anomaly at the 6:00 position on a transition weld.” “Transition” in this case means a spot where the pipeline changes from the thinner steel approved for most of the system to the thicker steel required under roads and in other areas where the pipeline might be subjected to greater weight.

DeSmog Blog says that’s exactly the sort of problem that whistleblower Evan Vokes (who has appeared in previous discussions of TransCanada’s unreliability) tried to warn his former employer TransCanada about:

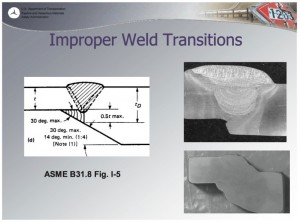

Vokes warned his former employer and PHMSA about the transition welds, which he described as “inherently risky.” Welding different thicknesses of pipe together is harder to do than welding the same thickness, and it is more difficult to get accurate X-rays of welds.

“Even a seasoned welding inspector could miss imperfect welds when reviewing X-rays used to check the welds during the pipeline’s construction,“ Vokes told DeSmog. “And any less than perfect weld is more prone to crack when the pipeline moves, which happens when weather conditions change.”

Vokes felt so strongly about the risk of leaky transition welds that he sent an email to TransCanada’s CEO Russ Girling, warning that the transition weldsused on the Keystone Pipeline were a bad idea.

He pointed out to Girling that TransCanada was ignoring an advisory PHMSA issued in 2003 that warned against the use of such welds because they are prone to crack under stress [Julie Dermansky, “TransCanada’s Keystone Pipeline Resumes Operations Under Supervision After South Dakota Dilbit Spill,” DeSmog Blog, 2016.04.11].

Vokes also notes that those armed guards TransCanada brought to the spill site violated safety regulations:

While reviewing photos that Cindy Myers, a member of the Dakota Rural Action group, took near the spill site, Vokes noticed a person on the pipeline right-of-way carrying a firearm. “Firearms are not permitted on a pipeline’s right-of-way,“ Vokes said. “This shows that the company and the regulators are not taking pipeline safety seriously. To ignore safety rules even when the public is present shows a total disregard of public safety” [Dermansky, 2016.04.11].

(Guns around pipelines and kids—we just don’t have a lot of common sense this month, do we?)

The PHMSA Corrective Action Order notes that when TransCanada found the bad weld, it was leaking oil at two drops per minute. That’s with the pipeline shut down. The order limits operating pressure at the Freeman pump station to 797 psi. TransCanada says the maximum operating operating pressure of Keystone is 1,440 psi.

PHMSA says TransCanada submitted a plan to fix the defect by installing a leak repair clamp. PHMSA orders TransCanada to submit a plan within 90 days to shut down the pipeline again, remove the clamp and the failed girth weld, and install a new section of pipe. TransCanada must also submit a plan “to analyze data on other girth welds within the Affected Segment”—from the Freeman pump station to the Hartington, Nebraska, pump station—”to develop a plan for the inspection of selected girth welds with similar characteristics.”

If regulators had not allowed TransCanada to use thinner steel to save money, there would have been no transition weld, and the Freeman leak may not have happened. Now TransCanada has to fix this leak and inspect other transition welds for defects. Pennywise, pound foolish, eh, TransCanada?

When the State Dept approved the thinner pipe, some of us practically screamed at the PUC that they should require another hearing on the matter, but they did not.

It’s not enough that a foreign company can come in and eminent domain private property all across the state and country, but then we need to allow them to pollute our land and water besides.

On another note, I heard over the weekend a reporter say that this is the first leak of the Keystone I. That is a crock of crap. Within the first year their was a leak up near the SD/ND border.

This is good information Cory. Twenty seven miles further south the Keystone 1 is bored under the Missouri River. I would assume that girth welds are used there also.

I hadn’t heard about TransCanada’s plan to do a temporary fix with a clamp. May I suggest some JB Weld instead. No sense spending a lot of money on some fancy clamp.

JB weld is good stuff. I patched metal water tanks for years with that stuff. A deadly battleship gray that stuff was after you mixed it up.

I believe there have been 14 leaks and 5 of them in South Dakota, Lanny.

http://visihow.com/images/8/8e/Yassora_1103151223-meme.jpg

Dakota Rural Action obtained Evan Vokes as an expert witness at last summers PUC hearing on whether to certify TransCanada’s permit. TransCanada attempted to portray Evan as a loose cannon, a sorehead whistleblower. Their efforts evidently worked with the three PUC commissioners.

A group of individual intervenors as well as three or four intervenor groups are challenging the PUC’s decision in a court of law. We say that TransCanada has not fulfilled the 50 conditions of the permit. This spill lends credence to our claim.

Very true,Bret. :) I got my giggles for the day. Thanks.

Good one Bret.

Cory’s post makes a very good point. TransCanada’s media person, Shaun Howard, has fed to the media that the pipeline is only leaking “one to two drops” per minute. This is when the pipeline is shut down. Let’s check it again, this time under the 1440 psi operating pressure. This is just another example of TransCanada’s disingenuousness.

The one to two drops per minute number is meaningless, anyone with a bad garden hose knows it leaks a hell of a lot more when you turn the water on than when the water is off.

Will the road be closed for the rest of the summer while TransCanada fixes this? Will the local farmers who normally travel this road be compensated for their extra expenses incurred while trying to conduct commerce now impeded by TransCanada?

What does the inspection of other transition joints entail? Test bores? Complete excavation? Why just inspect transition joints in one small segment of pipeline and not the entire pipeline?

One or two drops per minute? That pipeline had to be leaking before it was installed to lose 17,000 gallons.

The three idiots on the PUC lack the common sense, objectivity and expertise to approve pipelines like this one. Ramming the highly toxic bitumen sludge through a pipeline at higher pressure and temperatures is a lot more risky than operating common crude pipelines (which don’t have a great track record either). Leaving fundamental safety, construction integrity and monitoring up to a greedy foreign corporation like TransCanada is utter foolishness. The Evan Voke warning is proof that the foreign corporation is willing to ridiculous engineering risks with safety and the future of our drinking water resources.

The science behind the safety of these pipelines is not on TransCanada’s and the PUC’s side. The pipelines are expected to stay in the ground, operating for decades. Yet the problems associated with these higher pressure, hotter bitumen pipelines indicate that every mile of them hold the risk of leaks every day of every year until they are shut down and abandoned (oh, you thought they’d dig up the old lines when they’re done???). Not a matter of if, but when. Mile after mile. Day after day.

I think the three idiots on the board know exactly what is going on and have known from the get go. What we should be asking is who is gonna pay for this. I am thinking it will be South Dakota.

Using thinner steel for the pipeline sections under fields makes no sense- The tractors they’re using nowadays are as heavy as the trucks and more. Then there’s the near 10,000 gallon manure spreaders…

Any comment(s) from Jackley, Daugaard or the KXL cheerleaders from Washington, Dysfunctional City, yet? Such leaders-NOT!

mfi, I talked to a reporter from Rapid City this morning. She is going to call Gov Daugaard for a comment. Hope she doesn’t stop there, doubt that she will.

Thanks Paul. The guv seems busy. Did she need an appointment?

I suspect the reason this leak wasn’t detected by the pressure/flow rate monitoring system is because it has been leaking from day one. This story tends to fortify my suspicions.

mfi, she said that she’ll let me know what the guv says. Does Gov Daugaard know about the spill yet. If he does know he will probably issue a joint press release with TransCanada.

Armed guards, slipshod repairs, substandard pipes, and faulty welds bely a false concern for the safety.

Maybe no one in Pierre noticed there was a major oil spill. They aren’t to keen on noticing other shady activities. Maybe someone should go wake them fellas up. The party of personal responsiblity can’t even make a personal response to an oil spill in their state. Wither wingnuts.

In other news, the Nebraska Public Service Commission (their version of the PUC) is considering hiring a guy who used to work for TransCanada and now works for Enbridge to be the state’s director of natural gas and oil pipelines.

Day 60 Gazillion- South Dakota held hostage by TransCanada and STILL no official word from Officials. Any rotting corpses laying around Pierre?

Enbridge spill in Michigan. After a couple days,the chemicals in dilbit evaporate leaving a thick gluey goo that sinks in water and is almost impossible to retrieve using standard methods. Like tar.

TransCanada has claimed that the Freeman pipeline spill was only leaking at the rate of one to two drops per minute. There are 90922 drops in a gallon of water and TransCanada estimated the spill at 16,800 gallons. If the estimate of one drop per minute is used then this leak has been going on for 2906 years.

Very good researching,Paul.

I have kissed honey lips

Felt the healing in the fingertips

It burned like fire

This burning desire

I have spoke with the tongue of angels

I have held the hand of a devil

It was warm in the night

I was cold as a stone

But I still haven’t heard from the Governor!!!!

Read more: U2 – I Still Haven’t Found What I’m Looking For Lyrics | MetroLyrics

Figuring the Freeman spill another way. The Keystone 1 started pumping oil in July, 2010. That is around 2070 days. This figures out to 510 drops per minute. TransCanada’s Mark Cooper claimed a leak of one to two drops per minute.

Let’s figure it another way. The powers that be don’t appear to be concerned about this leak. They weren’t much concerned about EB-5. Didn’t show much interest in Gear-Up scandal. They do,however,love them some restrictions on lady bits. What is wrong with this picture?

Paul, did TransCanada ever clarify what they meant with that two-drop claim, whether they meant that was the observed rate of spillage when the pipeline was shut off or whether they were estimating how much was coming out under pressure?

Cory, the way that I understand it the first thing that TransCanada would do is shut the pipeline down so as not to cause pressure hammering. I don’t know the sequence for doing this but it would have happened on Saturday or Sunday. I was down there on Monday and they were striping topsoil off. I think that they got serious about excavating the pipeline on Tuesday. After the pipe was excavated TransCanada hired a third party metallurgist to estimate how much was leaking. He determined that it was leaking at one to two drops per minute. At this time the pumps were off, the valves were closed (at least the valve above the leak) and I presume the pipe had drained out at the leak site. PHMSA had not granted permission to restart the pipeline at this time.

I googled how many drops of water in a gallon. It is 90,922/gallon. I’m sure oil is different but this is close enough for me. The Keystone 1 was started sometime in July 2010. This is approximately 2070 days before the spill. There are 1440 minutes in a day. Now to mathify: 1440 minutes/day x 2070 days x 2 drops/minute = 5,961,600 drops. Divide this by 90,922 drops/gallon would give around 66 gallons that would have leaked at two drops per minute since the startup of the K1rather than the 16,800 gallons as estimated by TransCanada.

I would appreciate anyone pointing out an error in my calculations.

Your numbers make sense to me, Paul. The two-drop leak must be observed while the pipeline was shut down and was leakage from residual oil not already drained from the section south of Freeman.

I’m willing to believe that, at if the 400-barrel estimate is correct, this leak sprang this spring, as the ground heaved with the thaw, and when it leaked, it leaked more than two drops a minute.

Paul, how did you get to the site? Did you need a special pass to be allowed past the guards?

Cory, we did not get onto the site. Cindy Myers, a nurse from Stuart NE, and I met up that day and we drove to the top of the hill east of the spill site. We parked in the Hwy 18 road ditch and this is where Cindy took her pictures. I guess the regular news media didn’t think of this. Cindy’s photos have been shared all over the internet.

TransCanada must think that we are a bunch of idiots. First to claim that only 187 gallons had spilled and then to claim that 16,800 gallons leaked out at the rate of two drops per minute.